India can become a leader in the semiconductor industry by building a strong talent pool, offering solutions to the global supply chain challenges and encouraging collaboration between its academia and startups to foster innovation, industry experts said here on Thursday.

Speaking at a panel discussion at the Bengaluru Tech Summit 2023, Suraj Rengorajan, CTO, Applied Materials said the whole ecosystem needs to be put together to make India a “semiconductor nation”.

“India can be a solution to the global shortage of semiconductor talent and has the opportunity to play a role in the global semiconductor supply chain strategy,” he said.

India also has an opportunity to build sustainable solutions to drive the semiconductor industry.

“As the industry scales up, we need to ensure we have enough power and water to make it sustainable. Designing and building sustainable equipment is an opportunity for India,” Rengorajan said.

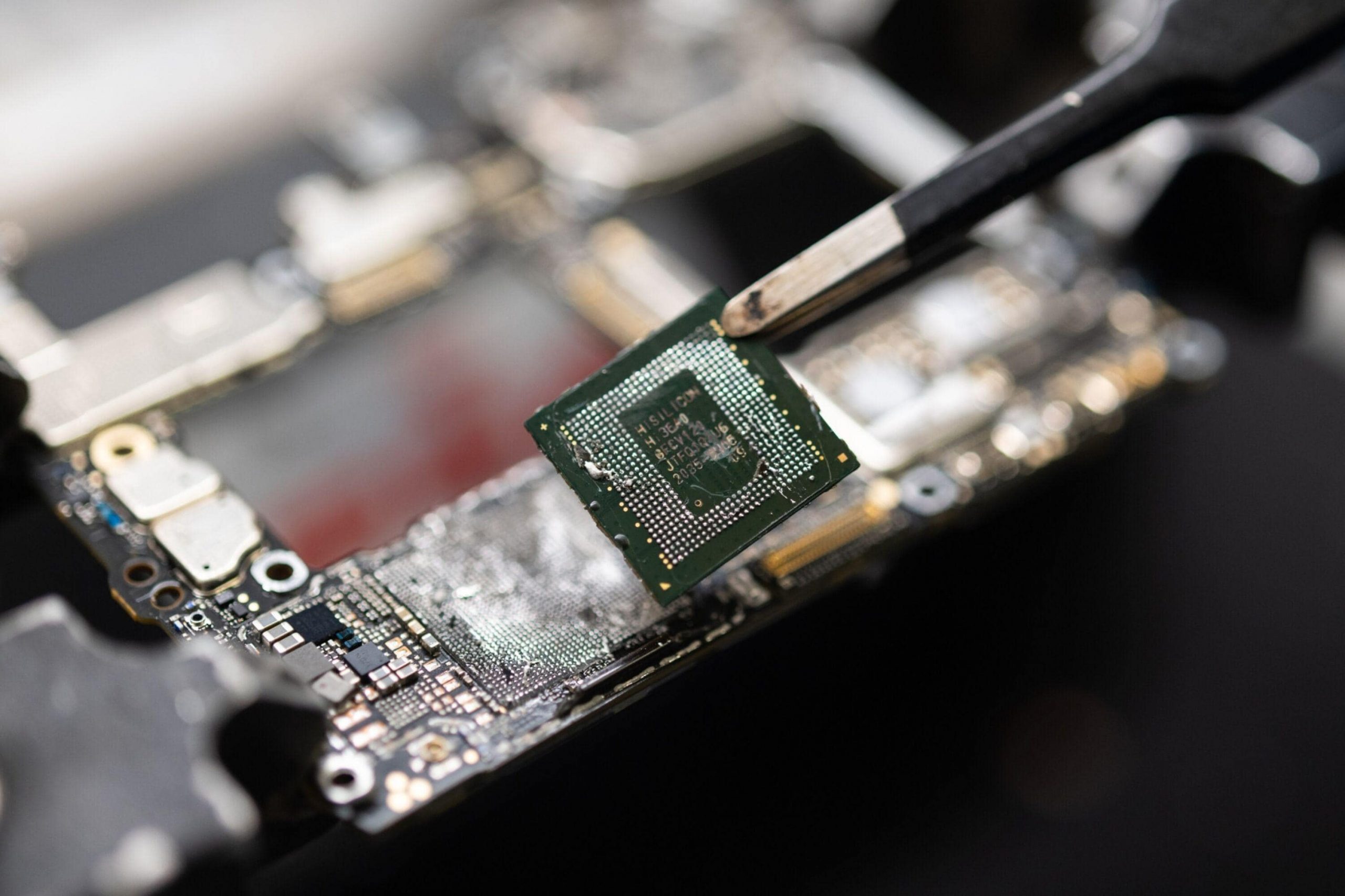

Hitesh Garg, Country Manager, NXP Semiconductors said all large companies have taken big strides in India when it comes to semiconductor design and innovation. “We have world-class academia too. The gap is in making India a manufacturing hub,” he said.

Garg said a collaboration with academia and startups to foster innovation in this area is one of the opportunities for India.

A lot of global semiconductor companies are already investing heavily in India. Earlier this week, Advanced Micro Devices (AMD) opened its largest global design centre in Bengaluru, as part of the company’s $400 million investment outlay, to expand research, development, and engineering operations in India.

The 500,000 sq. ft. campus plans to host about 3,000 engineers in the coming years, focused on the design and development of semiconductor technology including 3D stacking, artificial intelligence (AI), and machine learning (ML).

India’s semiconductor market is expected to touch $64 billion by 2026, almost three times its size of $22.7 billion in 2019, according to Counterpoint Research and the India Electronics & Semiconductor Association (IESA).

The manufacturing of semiconductor chips in India will be driven by domestic and export markets with significant demand from the consumer electronics, telecom, IT hardware, and industrial sectors.

In September, Micron Technology commenced construction of the first phase of a $2.75 billion semiconductor testing and packaging plant in Sanad, Gujarat. Similarly, Applied Materials said in June this year that it will invest $400 million over four years in a new engineering centre in India.

Note:- (Not all news on the site expresses the point of view of the site, but we transmit this news automatically and translate it through programmatic technology on the site and not from a human editor. The content is auto-generated from a syndicated feed.))